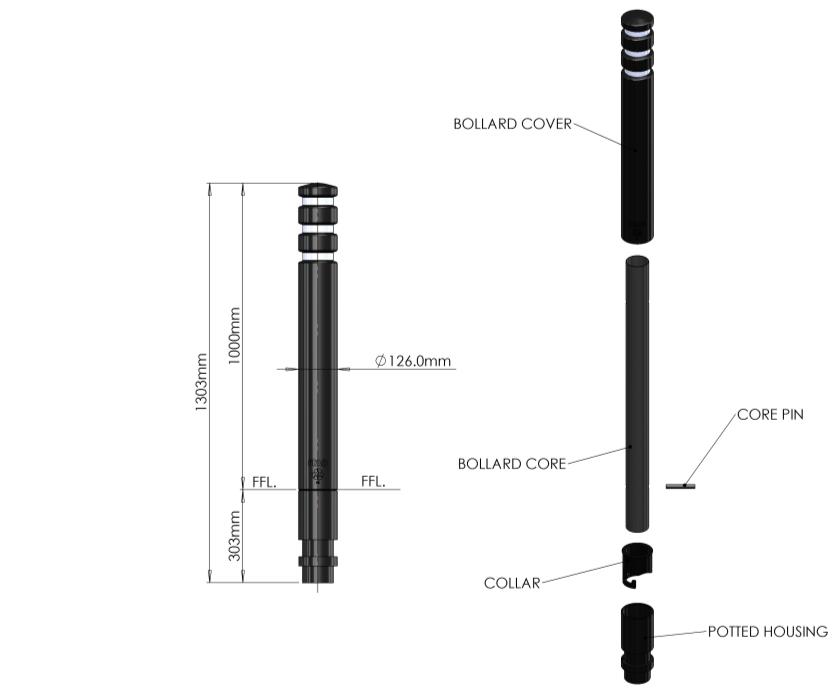

Description

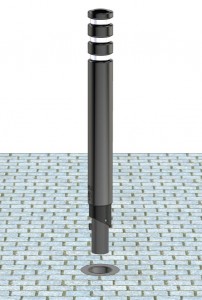

The most easily replaced bollard on the market.

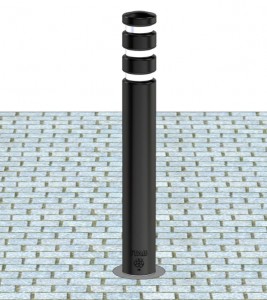

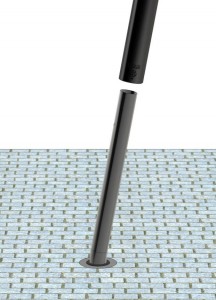

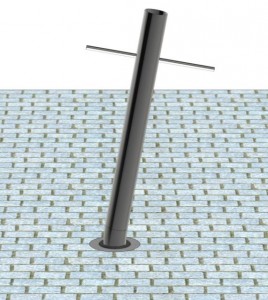

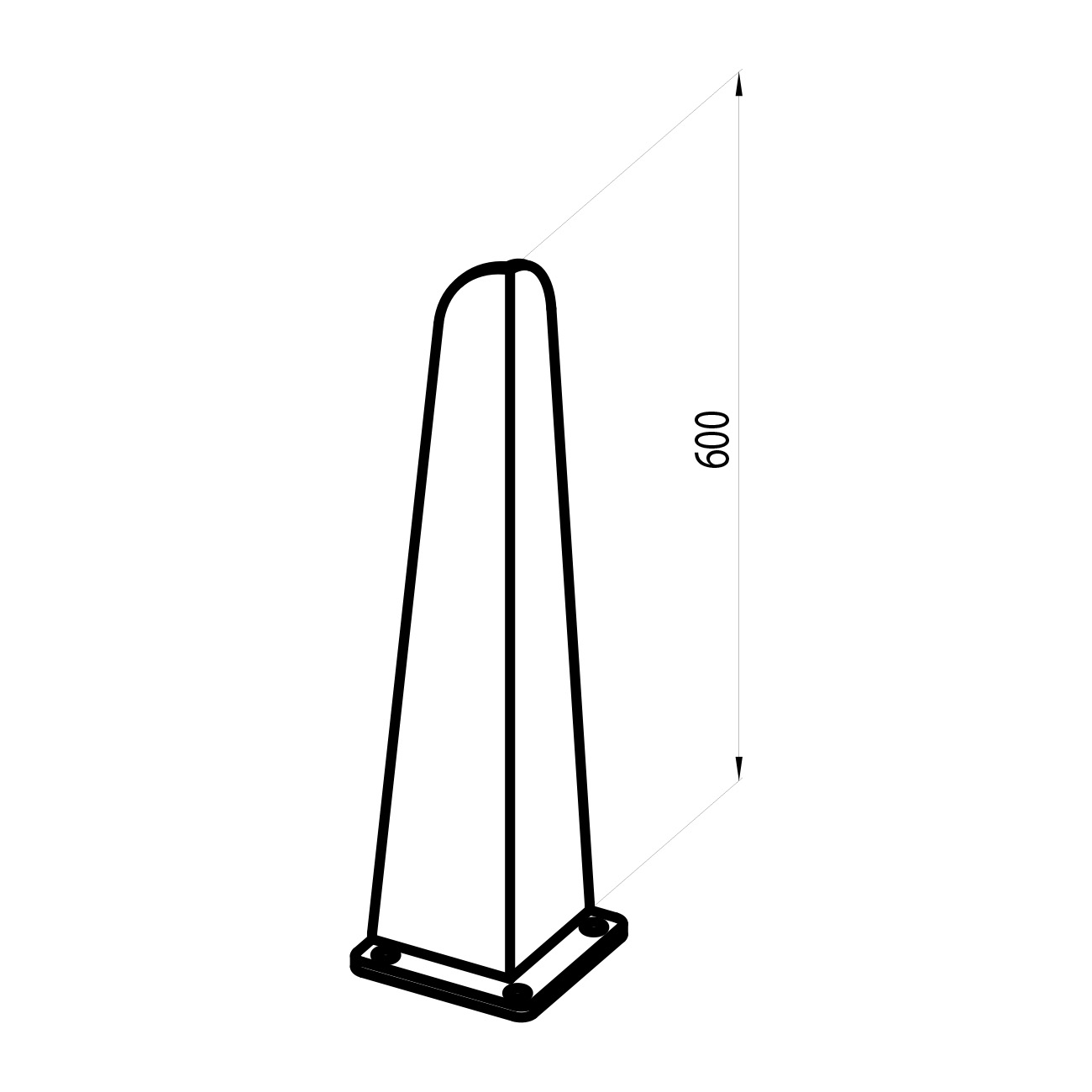

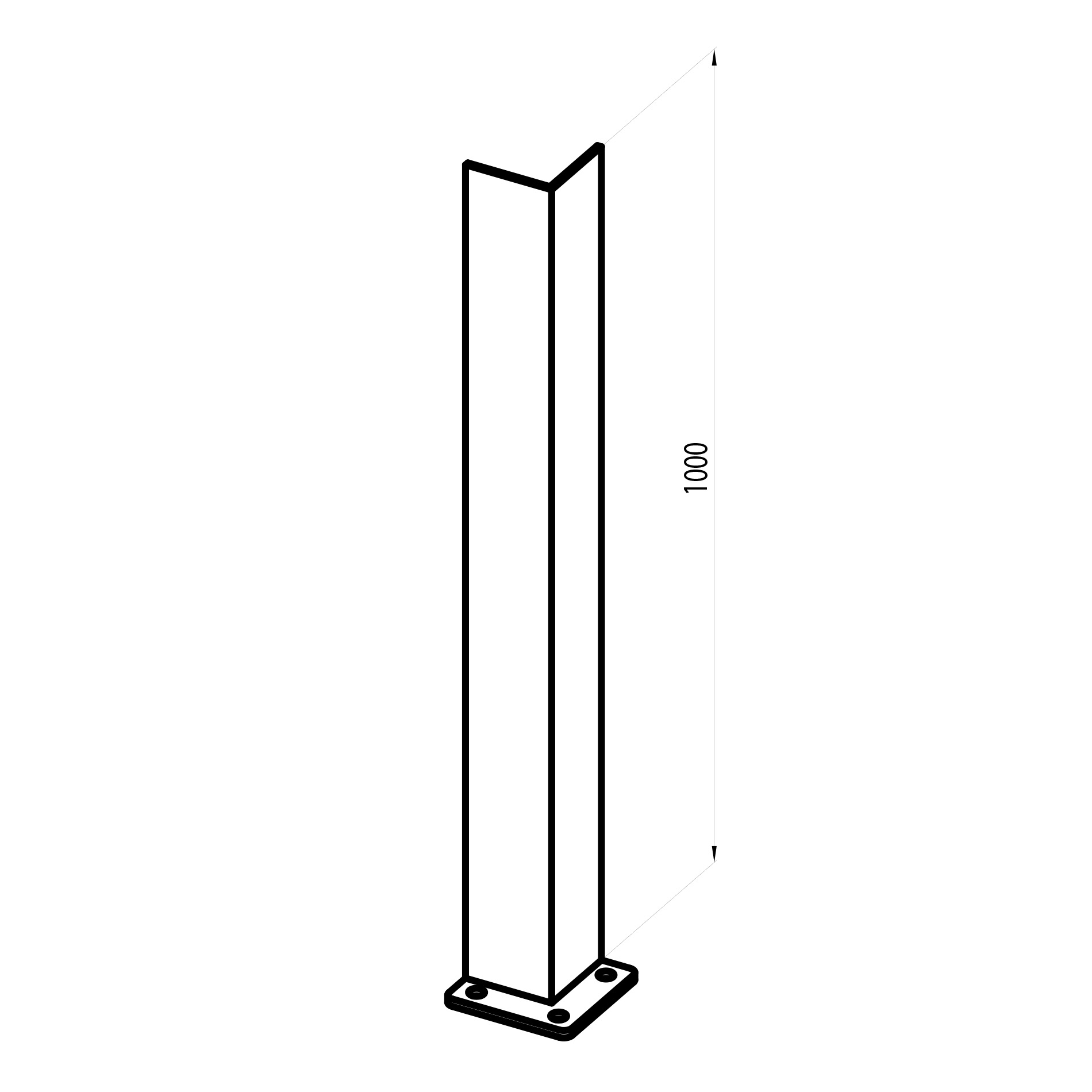

This unique external bollard reduces on-going maintenance costs in areas that are often damaged. They sit in a sleeve enabling the whole bollard including core to be removed and replaced without the need for expensive groundworks.

These bollards are must for any location that experiences repeated damage by eliminating the expensive repair bills.

Environmentally friendly – This bollard is made entirely from hard wearing plastic, and incorporates the plastic offcuts and other waste generated during manufacture.